Collaborating on a smart and efficient sorting system for plants

At Stofbergen Plant Company, a challenge was central: how do you make the sorting and packaging of plants more efficient without compromising on quality? Together with Stofbergen, we developed a system that perfectly aligns with their needs and working methods.

The strength of this collaboration lay in the combination of knowledge. Stofbergen brought their practical experience and in-depth plant knowledge, and we added our own expertise in plants, greenhouse horticulture, and automation. Together, we built an automated sorting line that automatically sorts plants by height and efficiently handles trays.

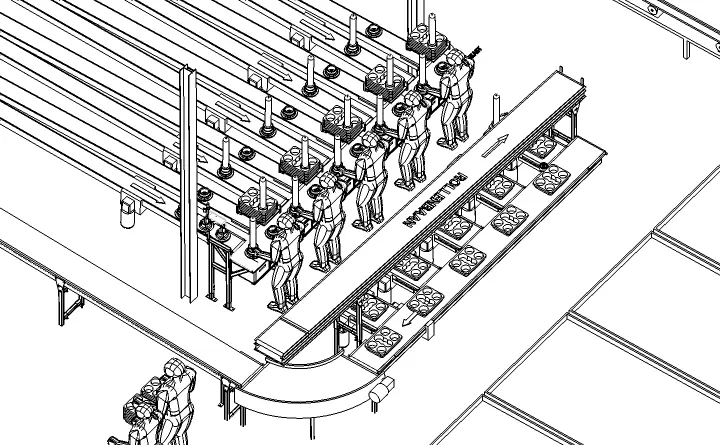

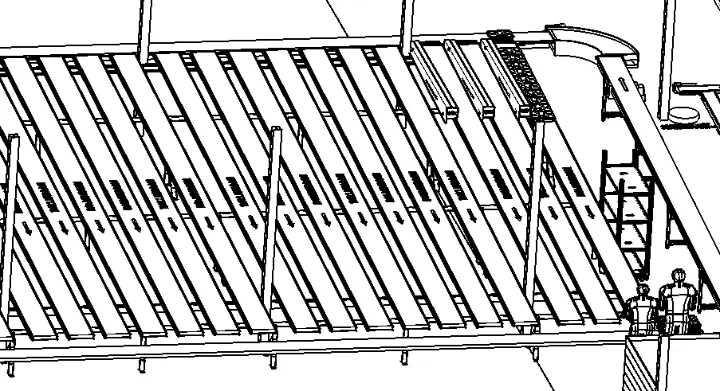

The process begins with unloading plants from the container. Through precise height measurement, the plants are distributed across five sorting belts. What makes this system unique is that Stofbergen Plant Company sets which plant lengths go on which belt. This keeps the sorting flexible and tailored to the plant varieties.

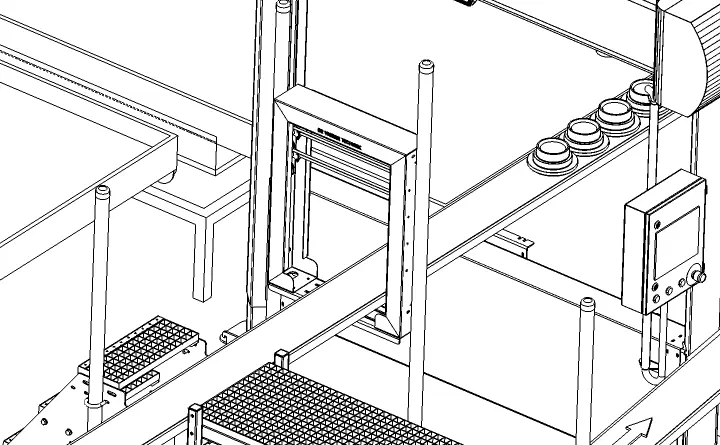

After the automatic sorting, the plants arrive at a workstation where employees manually clean and assess them. This combination of technology and craftsmanship ensures a reliable end result. The employee then places the full trays on a conveyor belt. The system automatically transports these trays to the correct delivery buffer, where a puller neatly draws the trays onto the roller conveyor.

What Stofbergen Plant Company also appreciated was that we made use of existing conveyor belts, retractors, and control components. This reuse contributes to sustainability and keeps costs low. During the installation, we jointly assessed which parts might need maintenance.

The main features of the system summarized:

- Flexible height sorting with adjustable sorting belts

- Manual cleaning and quality control

- Automatic transport and buffering of full trays

- Returning empty trays for reuse

- Smart reuse of existing materials

With this customization, the sorting line is capable of processing up to 1800 plants per hour, while the buffer can handle 400 trays per hour. This improves the flow without compromising quality or flexibility.

This customer case demonstrates how collaboration leads to a practical and future-proof solution. By combining our knowledge of greenhouse horticulture and technology, we have built a system for Stofbergen that does exactly what is needed: efficiently and reliably sorting and packaging plants.

“Through our joint efforts and the power of collaboration, combined with the years of practical experience of Vreede technology, we achieve goals that we could not have realized alone.” - Ed Stofbergen

Do you want a solution like that too? Get in touch.